Energy Audit on Ships: Audit of Marine Boiler

In continuation with the last article on energy audit on ships, we discuss the energy audit of the ship’s boiler. One of the major and important machinery on the ship, a marine boiler comes under special emphasis in an energy audit due to many well marked and potential energy saving areas.

A well maintained boiler is not only safe but is also fuel efficient.

Basic Steps of Boiler Audit

As discussed earlier, the steps involved in an energy audit are data collection, data analysis and making report.

- Data Collection: Finding how the ship uses steam, costs of fuel consumed per day and issues by reducing steam consumption for utilities. For example reduction of domestic hot water temperature or reduction of accommodation heating etc.

- Data Analysis: Identifying measures that would lead to energy conservation. These include measures with no investment, with medium investment and with large investment.

- Audit Report: The report has to be presented to the owners with the economic viability to enable making decision.

Instruments Required for Boiler Audit

In any energy audit the use of proper calibrated instruments is essential. The instruments that are required to carry out an in depth boiler energy audits are as follows:

- Portable Oscilloscope: It’s an all in one tool. It is used for visual display and interpretation of data, trend analysis, data logger, spectrum analyzer and measuring capacitance, resistance, continuity, AC and DC voltage, power measurement for single phase and three phase, total power, apparent power, reactive power, power factor, frequency and current etc.

- Infrared Remote Thermometer: It is used for temperature measurement and for finding hot spots.

- Tachometer: For speed measurement of motors and shafts as slippage of belts and lowering of speeds can cause improper air fuel ratio.

- Master Pressure and Temperature Calibrator: For calibrating the online instruments and sensors in the boiler control panel.

- Infrared Camera: This camera can take infrared photographs thus indicating trouble areas and hot spots.

- Flue Gas Analyzer: For analyzing flue gas and measuring concentration of O2, CO2, CO, NOx, and SOx etc.

- Ultra Sonic Leak Detector: It is used for checking steam traps that are leaking and pin-hole leakages of steam.

- Other Instruments: The other instruments that are used are digital manometers, calibrated pressure gauges, Multi meter, Clamp ammeter, Contact thermometer, Non contact water flow meter, power analyzer etc.

[the_ad id=’172861′]

Pre-audit Precautions

Before carrying out energy audit on the boiler some precautions must be taken to ensure accuracy and reliability of measurement.

- The boiler load should be kept constant during the audit.

- No soot blowing should be done during the audit.

- No blow down should be done during the audit.

Energy Conservation and Optimization opportunities

Depending on the layout of the ship, make of the boiler, the quality of maintenance and the condition of the boiler there may be some ship specific problems and recommendations; but in addition to these there are some common areas where generally loss of heat occurs and there is scope of energy conservation

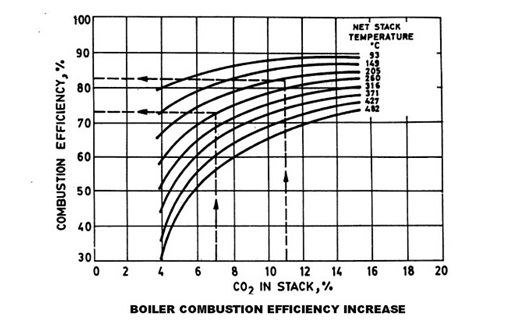

- Excess air in combustion: Specified quantity of air is required as per stoichiometric air fuel ratio for combustion. However as metering in inadequate some extra air is always supplied to avoid incomplete combustion. Excess air lowers efficiency because it does not take part in the combustion and takes away the heat of the furnace.

- Less air in combustion: If the air is less than the recommended stoichiometric air fuel ratio, incomplete combustion will result. Carbon will not fully burn to carbon-di-oxide but will partially burn to form carbon monoxide. This will cause loss of energy.

- Maximum Waste Heat Recovery: The funnel stack temperature must be as low as possible but with sufficient margin to be above the dew point to avoid sulphur corrosion. Generally a funnel temperature of 165 to 195 deg C when using Fuel Oil is considered optimum. In any case when the funnel (Exhaust Stack) temperature is higher than 200 deg C, a more stringent waste heat recovery program should be required.

- Feed Water Preheating: If the funnel temperature is higher than 200 deg C it can be utilized for feed water preheating, thus increasing the waste heat recovery. It will increase the overall efficiency of the plant

- Combustion Air Preheating: In case there is still a margin in funnel temperature combustion air preheating may be considered.

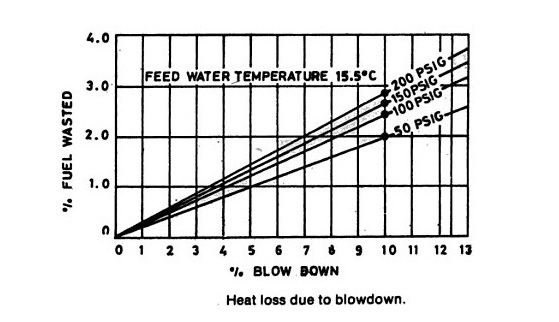

- Blow- Down Optimization: The blow down of the boiler is required for controlling the amount of TDS in the boiler. Blow down must be calculated and done after measuring the TDS amount. Some engineers merrily blow down the boiler excessively without need even when the parameters are in control and it results in loss of precious water and heat. Blow down must be done in response to the conductivity and the pH.

In the next article we will look into the areas of energy conservation and optimization opportunities and audit report.

References

- Boiler Operations By M P Murgai and Ram Chandra

- Training Manual for Energy Efficiency By Asian Productivity Organization, 2010

- Presentation on Energy Audit in Thermal Power Stations by H.S.Bedi

- Hand Book on Energy Audit and Environment Management by Y.P.Abbi and Shashank Jain

- Working manual on Energy Auditing in Industries By Asian Productivity Organization

Do you have info to share with us ? Suggest a correction

About Author

Chief Engineer Mohit Sanguri is a Marine Chief Engineer (Class I Unlimited Power). He has 12+ years of experience as a Marine Engineer.

Latest Marine Technology Articles You Would Like:

Related Posts

- Blow-Down Procedure for Marine Boilers

- 6 Practical Tips On Improving Boiler Efficiency for Professional Marine Engineers

- What To Do During Marine Auxiliary Boiler’s Flame Failure or Fuel Pump Tripping?

- Boiler Starting Failure – Troubleshooting

- Understanding Boiler Feed Water Contamination

- Understanding Boiler Refractory And Its Types

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

great article on boiler energy conservation.

do you guys think that stopping the auxiliary boiler water circulation pump when the exhaust gas boiler is not running will save some thermal energy?