The Science Behind Marine Boiler Water Circulation on Ships

The most important aspect of any marine boiler is maintaining the correct water level. As the boiler fires, steam liberates from the surface of the water and thus as the steam gets consumed, there is subsequent drop in water level inside the boiler.

Steam gets produced only when there is an effective circulation of water within the boiler. For tank type boilers, circulation is not distinct and the water circulates within the tank of the boiler itself. For water tube boilers, circulation is necessary within each and every tube and headers.

This happens naturally if both the steam and water drums are connected with tubes. But there is some basic design reason which has to be emphasized on.

Natural Circulation within a Water Tube Boiler

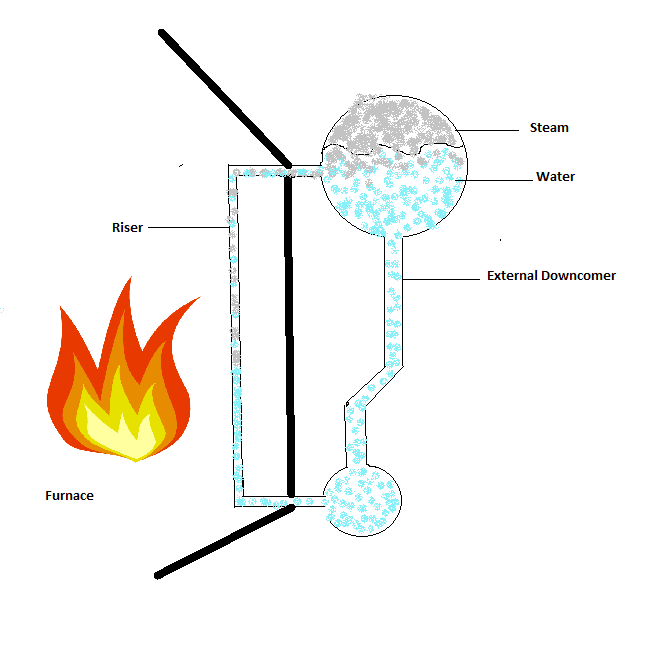

The steam drum and water drum may or may not be separated depending upon the boiler design. To understand the boiler water circulation principle, we will assume the following components to be separate. A steam drum at the top is connected to the water drum at the bottom through down comers outside the boiler shell and risers inside the boiler shell.

Cold water is fed to the top drum/steam drum, by water feed pump through a screw down non-return valve and a check valve. As we all know, hot water stays on top and relatively cold water (being denser) travels to the bottom of the drum.

The steam/water drum has down comers connecting to the water ring at the bottom of the boiler. The down comers are located outside the boiler shell and are large in diameter when compared to the water tubes.

As the cold water from the down comers reach the water ring in the bottom, the circulation starts within the tubes and drums. As the water particles enter the water tubes, which are inside the boiler furnace, they start to heat up and become wet steam with some bubbles. As they are less dense, they immediately rise up to the steam drum and thus are continuously being replaced by relatively cold water from down comers. Thus boiler water circulation happens naturally inside a water tube boiler.

Design Aspect

If the circulation has to happen in a natural way, then there are some design considerations to be observed. Ratio between the amount of steam leaving the risers & the amount of water entering the down comers is of the order 4:1.

It is important to have more water than steam on the risers. If the riser at some point becomes completely full of steam, the tube would over heat and “BURN OUT”.

“BURN OUT” is where the tube metal over heats can no longer resist the pressure forces within the tube and thus ruptures.

Reasons for having External Downcomers

It is known that as the pressure and temperature increases, the density of water decreases. Thus the density difference between water and the steam reduces & thus at higher pressures, the natural circulation of water-steam is impaired.

Thus to maintain the natural circulation, external, unheated down comers are fitted. These external down comers are large bore tubes connecting the steam drum with the water drum.

You may also like to read-Boiler Mountings: A Comprehensive List

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

Related Posts

- Blow-Down Procedure for Marine Boilers

- 6 Practical Tips On Improving Boiler Efficiency for Professional Marine Engineers

- What To Do During Marine Auxiliary Boiler’s Flame Failure or Fuel Pump Tripping?

- Boiler Starting Failure – Troubleshooting

- Understanding Boiler Feed Water Contamination

- Understanding Boiler Refractory And Its Types

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

How to make boiler working with heating oil working with diesel/solar?

Contact details of Sriram Subramanian please

Please send us an email with the subject, we will forward it to Mr. Sriram.