Procedure for Entering an Enclosed Space on a Ship

A ship is a complex structure from inside with several small and enclosed spaces. Many of these enclosed spaces are used for installing some machinery or for storing machine parts or workshop equipment.

A ship has a matrix of pipelines, which runs through each of its parts, including enclosed spaces. An enclosed space can be used for several reasons; however, the main issue arises when one has to enter these enclosed spaces in order to do some repairing work or for cleaning purposes.

Unfortunately, numerous incidents involving personal injury, loss of lives, enclosed space casualties have been reported off late due to failure to follow correct entry procedures.

Even though shipping companies issue warnings about the dangers and provide relevant training, too many seafarers are still dying or are severely injured.

Related Read: New FREE eBook: A Pocket Guide To Safe Confined Space Entry On Ships

What is an enclosed pace and what are its characteristics?

An enclosed space is a space that is not used for day to day activity and which has any of the following characteristics:

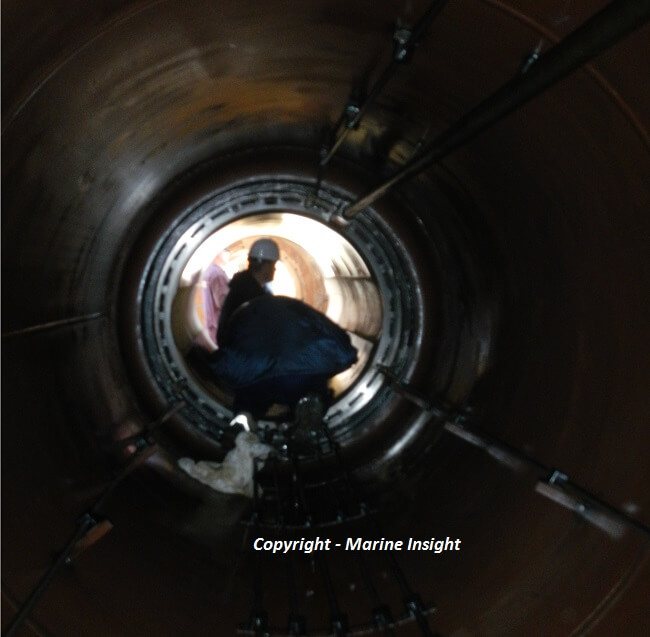

1. Limited opening for entry and exit

2. Inadequate ventilation

3. Is not designed for continuous worker occupancy

The presence of any one of the characteristics as stated above can make space an enclosed space. A ship-specific list should be available to identify all enclosed spaces on board and should be displayed in public spaces. The most common confined spaces onboard ships are cargo holds, chain lockers, cofferdams, water tanks, void spaces, duct keels, fuel tanks, engine crankcases, exhaust and scavenge receivers.

Related Read: 11 Important Points To Consider While Cleaning Tanks On Ships

Any area on the ship that has been left closed for any length of time without ventilation must be considered dangerous. Changes in the environment of a space that is not labelled unsafe can also make space unsafe, for example, failure of fixed ventilation or the migration of hazardous vapours from an adjacent hazardous space.

It is best practice not to enter a dangerous space, however, onboard crew members have to enter enclosed spaces for a number of reasons including routine inspection of tanks (ballast tanks, DB tanks), checking if a tank is dry before loading, cleaning of tanks or holds, maintenance including painting, repairing, etc.

Dangers and hazards associated with enclosed spaces can be –

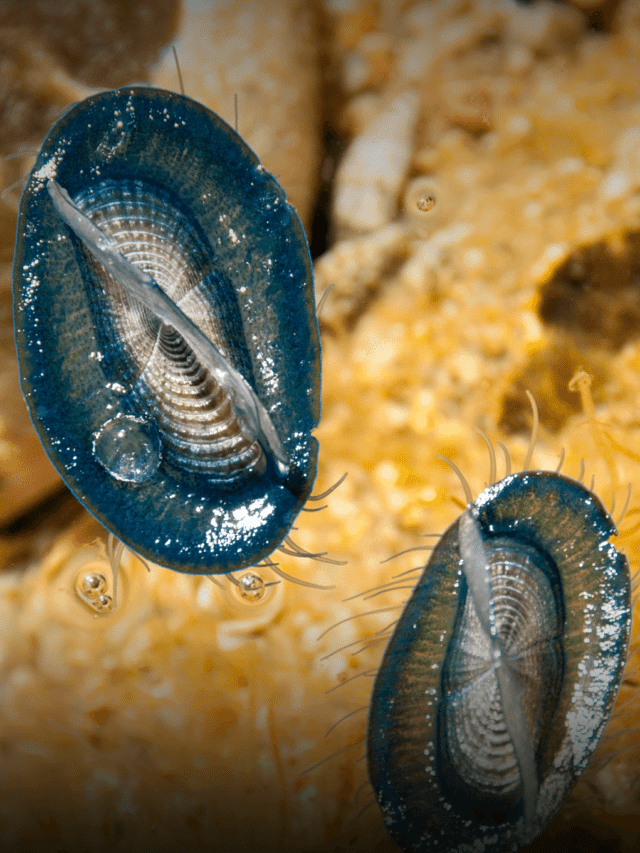

1. Lack of oxygen – the acceptable range of oxygen in an enclosed space is between 19.5% to 23.55. Oxygen in any compartment can reduce due to many factors- rusting of steel parts is the most common one. We all know that rusting is nothing but the process of oxidation-thus oxygen is consumed. Oxygen can also be consumed by activities like hot work, welding or the occurrence of fire.

Related Read: Practical Tips for Safe Gas Welding and Cutting Operations On Ships

Inert gases entering the space can also deplete the oxygen content. The remaining traces from discharged cargoes such as iron ore, coal can absorb oxygen.

2. Hazardous vapours– The presence of toxic vapours can make space deadly even if there is no lack of oxygen or the compartment is oxygen-enriched. A person may suffer from eye irritation, headache or even become unconscious if he/she inhales toxic gases. A higher concentration of toxic gases can also cause death.

3. Leakage of hazardous materials from adjacent spaces.

4. Insufficient/no ventilation – there could be high chances of the presence of toxic gases or absence of oxygen, both cases being lethal for man entry.

5. Restricted space– restricted or limited space in any compartment can make rescue attempts from such chambers difficult and challenging. Personnel should understand the layout of an enclosed space before attempting entry.

6. Inadequate lighting.

7. Personal injury due to slips, trips, and fall.

Because of zero ventilation, these enclosed places generate and store toxic gases which are either produced from chemicals stored in the place or leakage from pipelines. If a person enters such a place without taking precautions, he or she may suffer unconsciousness and sometimes even death.

There have been many accidents in the maritime industry related to enclosed spaces that have not only caused health hazards but also have costed their lives.

In spite of stringent checklists, permits to work, our fellow seafarers are still losing their lives.

Below we have enumerated some of the main issues that are often overlooked.

- Failure to recognize dangerous enclosed spaces and all hazards associated with them

- Lack of awareness on the hazards of what is carried onboard

- Unplanned and poorly executed rescue attempts

- Lack of understanding or non-compliance with company procedures, checklists should not be treated as a tick box exercise. The vessel safety management system should be implemented properly. A range of safeguards exist to protect against accidents and injury in enclosed spaces, and these should be taken seriously. Checklists are prepared for a reason. Keeping to the procedures is the rescuer’s first defence against injury or death.

- Incorrect use of critical safety equipment

- Failure to carry out necessary safety precautions

- Unplanned and poorly executed rescue attempts

- Acting on emotion and instinct and disregarding knowledge and training- people believe it won’t happen to me. Impulsive behaviour can be fatal. It is human nature to want to save a colleague, and in this thought, rescuers rush in without taking proper safety precautions.

- Lack of intervention.

Related Read: Enclosed Space Ship Safety Rule Enters Into Force

To prevent such unfortunate circumstances, there is a proper procedure that needs to be followed for the safety and wellness of the person entering the enclosed space.

Procedure for Entering an Enclosed Space

The following are the points that need to be followed before entering an enclosed space:

- Risk assessment to be carried out by a competent officer as enclosed or confined space entry is deficient in oxygen, making it a potential life hazard

- Risk assessment is one of the core preparation tools for enclosed space entry. It is designed to minimize the possibility of accidents by dealing with every aspect of the entry, identifying the hazards, deciding the control measures and finding alternatives or solutions or means to mitigate the risks. RA should be performed every time before man entry

Related Read: How Deck Officers Should Do Risk Assessment On Ships?

- A list of work to be done should be made for the ease of assessment for e.g. if welding to be carried out or some pipe replacement etc. This helps in carrying out the work quickly and easily

- Potential hazards are to be identified such as the presence of toxic gases

- Opening and securing has to be done and precaution should be taken to check if the opening of enclosed space is pressurized or not

- All fire hazard possibilities should be minimized if hot work is to be carried out. This can be done by emptying the fuel tank or chemical tank near the hot workplace

- The confined space has to be well ventilated before entering. Enough time should be allowed to establish a ventilation system to ensure that air containing enough oxygen to sustain life is introduced. Ventilation can either be natural or mechanical using blowers.

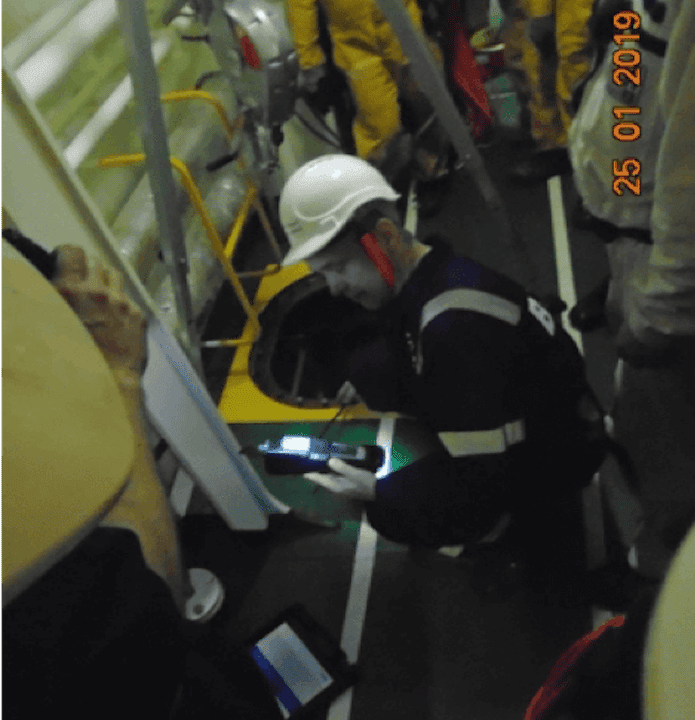

- Space has to be checked for oxygen content and other gas content with the help of an oxygen analyzer and gas detector. Atmosphere testing instruments should be able to measure the presence of carbon monoxide and hydrogen sulphide. Tests should be carried out at different levels of the enclosed space, the top, middle and the bottom and through as many openings as possible to obtain a representative sample of the atmosphere in the space. Exposure to even 2 to 5 ppm hydrogen sulphide atmosphere can cause headache, nausea and teary eyes.

| METHANE – RISES TO THE TOP AS IT IS LIGHTER THAN AIR |

| CARBON MONOXIDE– STAYS IN THE MIDDLE AS IT IS THE SAME WEIGHT AS AIR |

| CARBON DIOXIDE – SINKS TO THE BOTTOM AS IT IS HEAVIER THAN AIR |

- The oxygen content should read 20% by volume. A percentage less than that is not acceptable and more time for ventilation should be given in such circumstances.

- Enough lighting and illumination should be present in the enclosed space before entering

- A proper permit to work has to be filled out and a checklist to be checked so as to prevent any accident which can endanger life. A confined space should only be entered with an authorised and issued permit and by a trained and competent person. The permission to work in an enclosed space specifies:

– The location of the work

– The nature and limitations of the work

– Details of the working team and tools to be used

– Potential hazards

– Precautions are taken

– Protective equipment to be used

– Time of issue and its validity

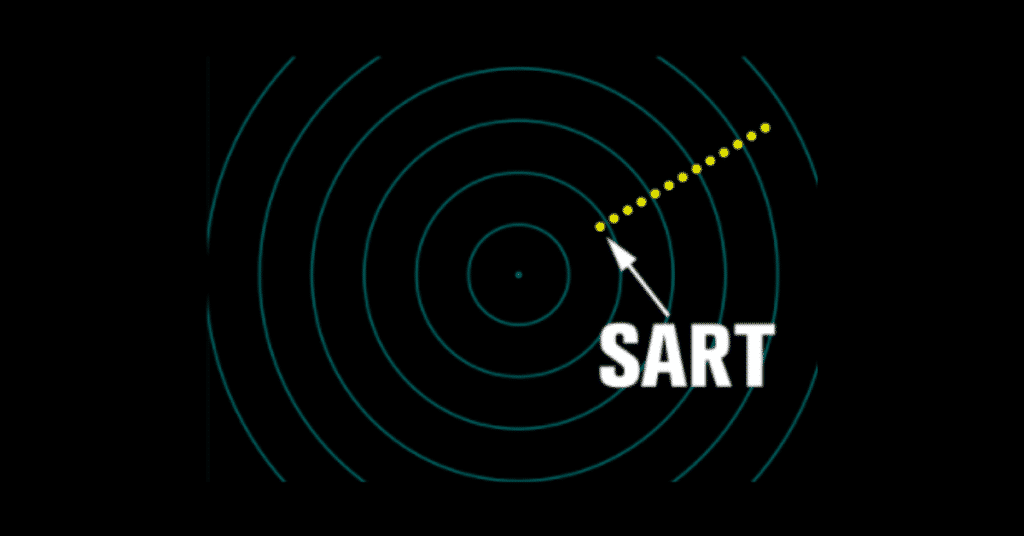

– Agreed communication methods and intervals

– Signature of the person on issuing the permit and on completion of the work

– Signature of the person who is supposed to enter thus confirming he has been advised on the hazards and the precautions to be observed

- Permit to work is to be valid only for a certain time period. If the time period expires then again new permit is to be issued and the checklist is to be filled out.

- Permit to work has to be checked and permitted by the Master of the ship in order to work in a confined space

- Proper signs and Men at work signboards should be provided at required places so that person should not start any equipment, machinery or any operation in the confined space endangering the life of the people working

- The duty officer has to be informed before entering the enclosed space

- The checklist has to be signed by the person involved in entry and also by a competent officer

- One person always has to be kept on standby to communicate with the person inside the space. Effective communication between the people inside the space and the person standing by is vitally important. The communication system must be agreed upon and tested. The standby person must, in turn, be able to communicate with the officer of the watch

- The person may also carry a lifeline with him inside

- The person should carry an oxygen analyzer with him inside the enclosed space and it should be on all the time to monitor the oxygen content. As soon as level drops, the analyzer should sound alarmed and space should be evacuated quickly without any delay

- No source of ignition has to be taken inside unless the Master or competent officer is satisfied

- The number of persons entering should be constrained to the adequate number of persons who are actually needed inside for work

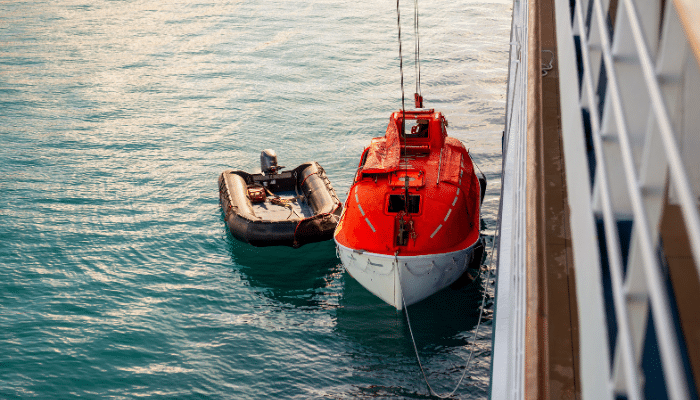

- The rescue and resuscitation equipment are to be present outside the confined space. Rescue equipment includes breathing air apparatus, spare charge bottles, stretchers, means of hoisting an incapacitated person from the space like a tripod, rescue harness, portable lighting, etc.

Related Read: How to Rescue a Person from a Confined Space on a Ship?

- Means of hoisting an incapacitated person should be available

- After finishing the work and when the person is out of the enclosed space, the after-work checklist has to be filled

- The permit to work has to be closed after this

The above-mentioned procedure is extremely important to enter an enclosed space. These points are imperative to risk any crew member’s life while entering a confined space.

It is of paramount importance that enclosed space entry drills are carried out on board. Drills should be realistic and effective and must involve the active participation of all crew members.

Related Read: 10 Important Safety Drills and Training Procedures

Regular drills help crew members to understand and anticipate the dangers of enclosed spaces, the rescue procedure and equipment are to be used. It gives valuable hands-on experience and the confidence needed in a real emergency. On completion, drills should be evaluated to identify improvements.

Enclosed space drills have been made mandatory since 1st January 2015 and should be carried out every two months. Every crew on board should be encouraged to speak up when they feel something is wrong.

If you do not understand seek clarification. Proper supervision and coaching are required for new joiners so that they understand and anticipate the dangers of enclosed spaces.

You may also like to read Procedure for cleaning Boiler on a ship.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Latest Ship Safety Articles You Would Like:

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

In STCW 2010 what is newly added compare with 1995

A very interesting article . I noted in your post you stated that oxygen content should read 20% by volume. Following guidelines from COSWP and ICS this should in fact be 21%. In addition you did not mention the following critical pre-checks:

1) Calibration of oxygen meter (Fresh air calibration)

2) Permit to open tank (Maersk specific procedure)

3) Line blanking or closure to avoid accidental filling( Lock out)

4) Continuous radio or pre determined communication method ( Special reference to hermitically safe radios)

Either way it was a good read

Things are good.

But one thing what are the activities conducted within an enclosed space

Sir, good evening

I just want to ask what are the procedures to prevent corrosion on enclosed spaces due to oxidation

Thank you very much sir