Water-in-Fuel Emulsion and Homogenisers – Working & Advantages

Environmental protection has become a huge priority globally, and it is no different in shipping. Therefore, the need for environment-friendly technologies has paved the way for the advent of water-in-fuel emulsions. These offer multiple benefits of reduction in NOX, soot and particulate matter apart from better combustion, consequently lesser maintenance & lower fuel consumption. Let us see how.

One benefit is gained through the use of the homogeniser. The homogeniser breaks down the fuel particles, reducing their size considerably.

It helps in maximising the benefit of Water-in-fuel emulsions.

The smaller fuel droplets help enhance combustion quality by better mixing with the compressed air & even distribution in the combustion chamber. This also helps in reducing fuel consumption, soot & particulate matter.

In addition to this, due to the air-fuel mixture in the combustion chamber being homogeneous, excess air consumption is reduced, resulting in a reduction of Nitrogen, which is present in air, & NOx.

Another benefit is gained through the use of water injection. A small volume of water (generally less than 10%) is added to the fuel to create a water-in-fuel emulsion. This emulsion passes through the homogeniser and is broken down into smaller droplets of emulsified fuel before being injected into the cylinders.

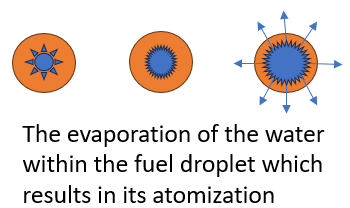

This emulsified fuel, when injected into the combustion chamber, comes in contact with the hot compressed air, and the water droplet inside the emulsion starts to evaporate.

As the water turns into steam, it atomises the fuel, which results in even smaller droplets & better distribution of the fuel in the combustion chamber.

The steam also has a cooling effect, which tends to reduce the combustion temperature, thereby resulting in a reduction of NOX.

Let’s discuss the system, components & its operation in detail.

Location, components & Operation

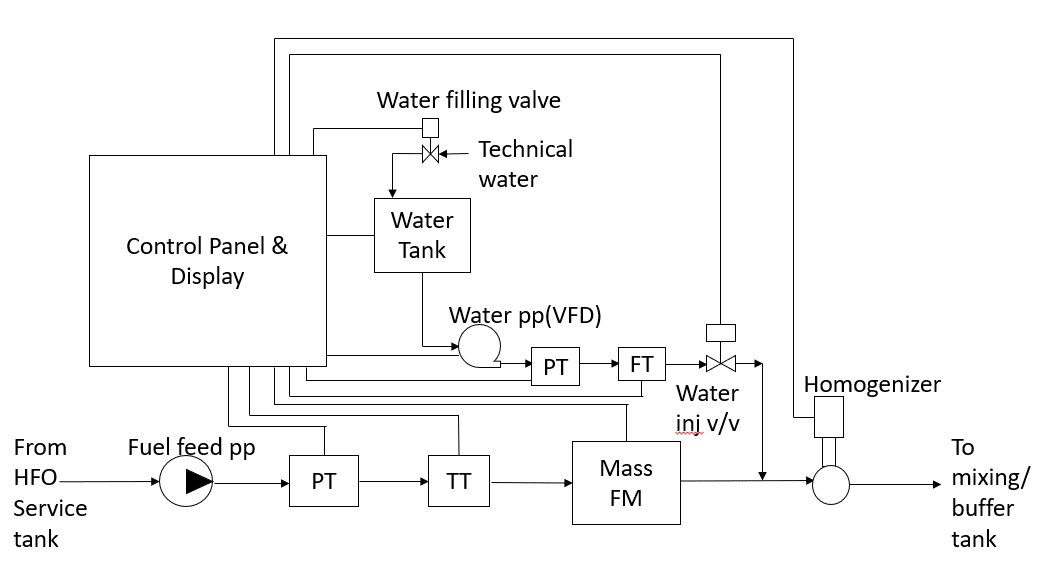

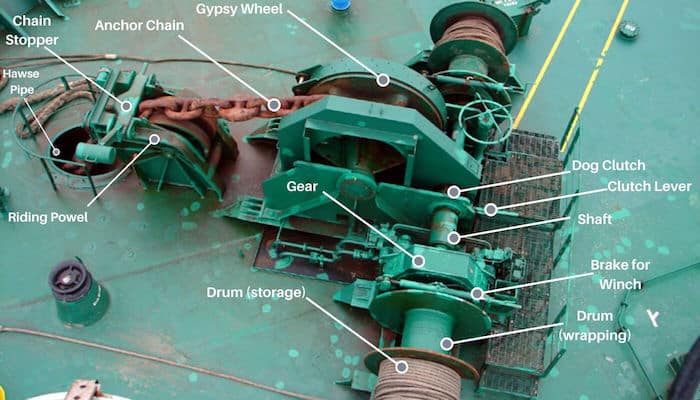

The Water-in-Fuel Emulsion (WFE) unit consists of a main control unit with a display, a water tank with an automatic solenoid-operated water-filling valve, a water pump with a variable frequency drive (VFD), water pressure & flow transmitters, water injection valve and a homogeniser. All these components are linked to, controlled and regulated by the main control unit.

Distilled water from the ship’s freshwater generators is the preferred and recommended medium of water used for the emulsification process. However, potable water may also be used in case of non-availability of distilled water.

The level of the water tank is sensed, and the water filling valve is opened by the control circuit for automatic replenishment when the system is in operation.

The WFE unit is located in the fuel supply line to the engines just after the fuel feed/supply pumps but before the mixing/buffer tank. This location is chosen for the system to be able to precisely add the correct percentage of water according to the flow of fuel to the mixing tank.

A flow meter fitted in the fuel supply line detects the flow of fuel and transmits it to the main control unit of the WFE. The control unit then adjusts the amount of water injected according to it.

The unit is designed to operate by itself (start/stop automatically) according to temperature, pressure & flow of fuel.

Along with the flow, the fuel pressure & temperature are also sensed by the control unit through pressure & temperature transmitters. It is designed to stop automatically when fuel is changed over from HFO to MDO and start when changed over from MDO to HFO. This ensures that the WFE system remains off when on diesel and starts only when HFO is flowing.

WFE unit has obvious benefits, which are listed below.

Benefits of the WFE system

- Reduction in Particulate Matter emissions & soot.

- Improvement in fuel efficiency by up to 2%.

- Reduction in emissions by up to 90%.

- Less requirement of air for combustion, which consequently results in less Nitrogen and, consequently, less NOx. (10% water added can bring a 10% reduction in NOx.)

- About a 60% reduction in visible smoke at the start & low loads and up to 30% reduction at medium to high loads.

- Reduction of carbon dioxide because of improved SFOC (energy efficiency)

- Cleaner, more efficient diesel generators, turbochargers and economisers, exhaust manifolds, silencers, Exhaust Gas Cleaning System towers and funnel ducts.

- Lower risk of water carryover from the funnel.

- It comes as a compact unit, thus occupying less space.

- Requires little to no maintenance

Homogeniser

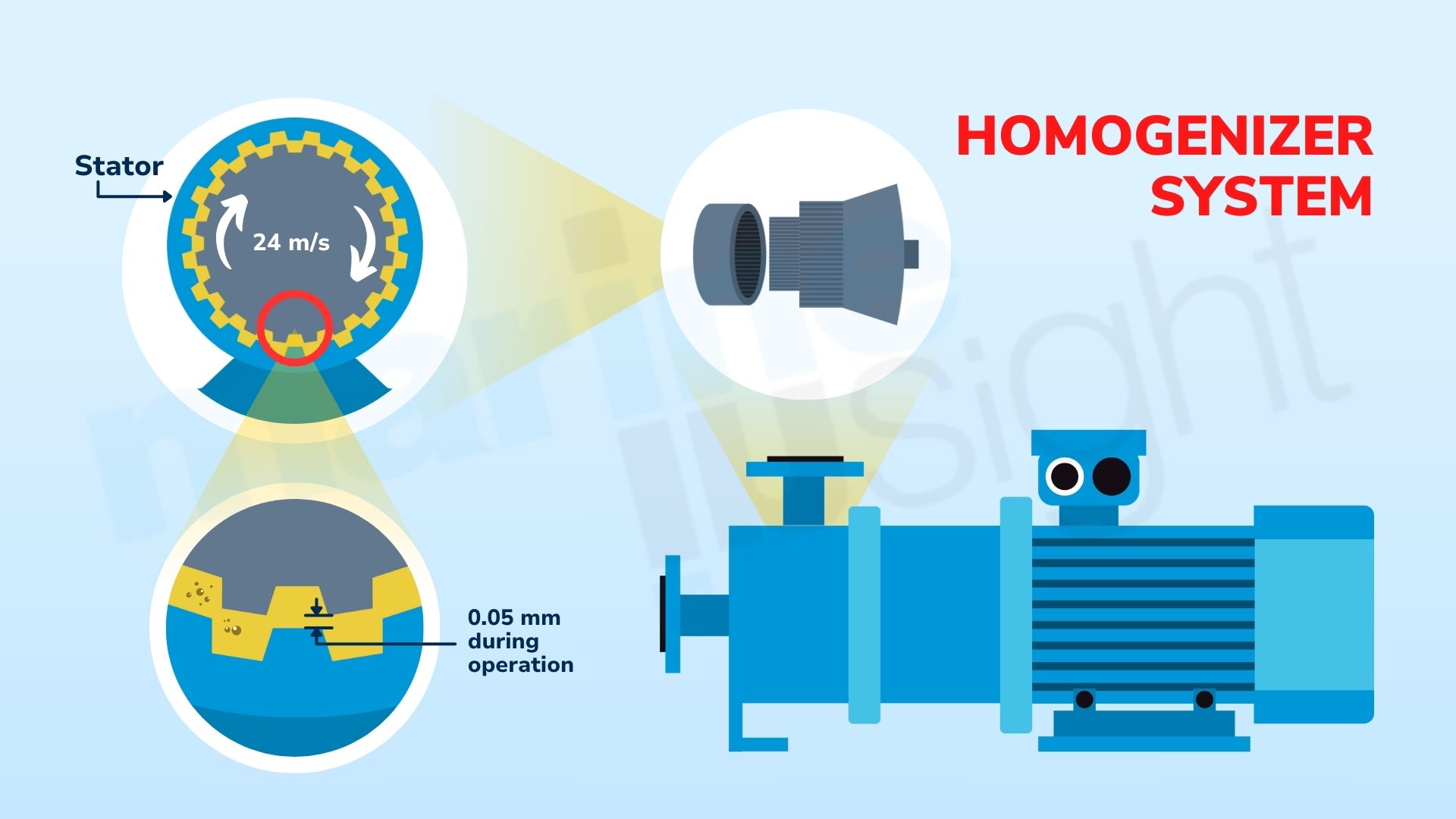

As mentioned briefly earlier, the homogeniser is the component that helps in maximising the benefit of the WFE. It breaks down large-sized fuel particles in the range of 60-70 microns to a much smaller size, about 2-5 microns, thereby breaking them down to a much smaller size than their original molecule size.

This helps in a much more homogeneous spread of these smaller fuel molecules in the combustion chamber. This results in better combustion and a gain in fuel efficiency. In fact, about 70% of the benefit of the WFE is derived from the use of the homogeniser.

The combination of the homogeniser with the WFE is discussed below.

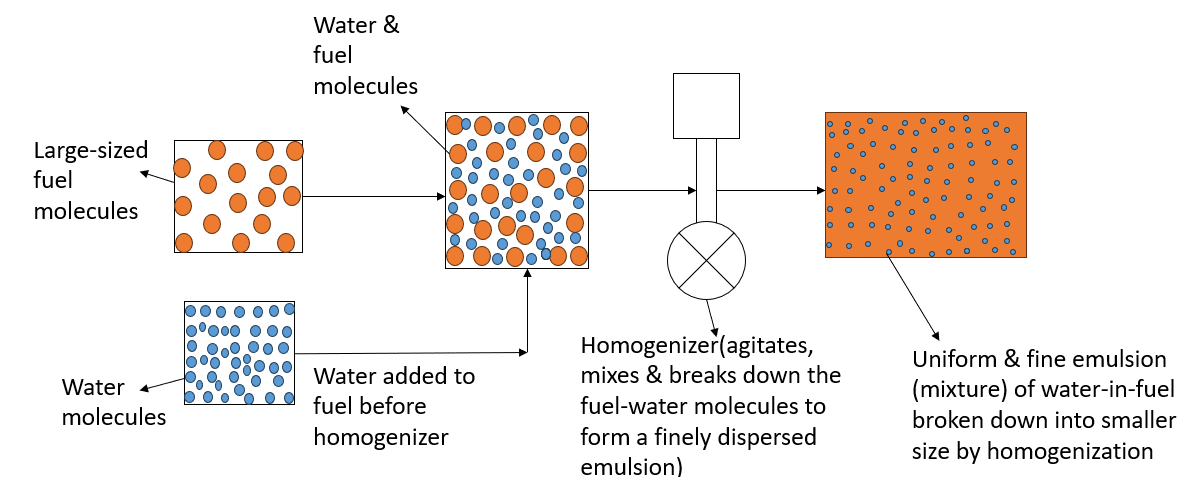

Water is added to the large-sized fuel molecules from the fuel oil service tank. The Fuel & water molecules co-exist without mixing, but they have to be mixed well & broken down to a much smaller size. This is achieved by the homogeniser.

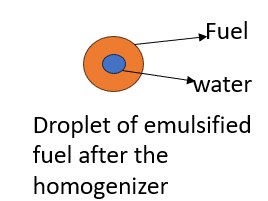

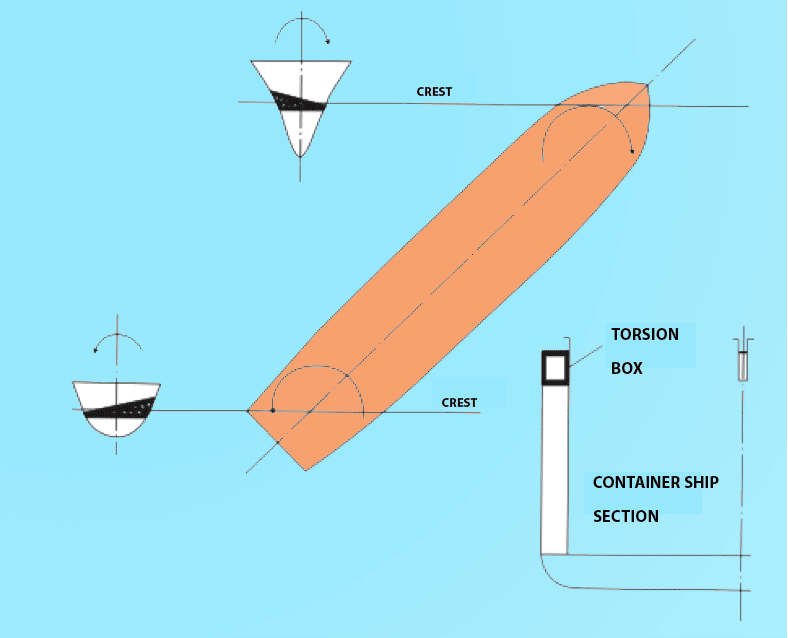

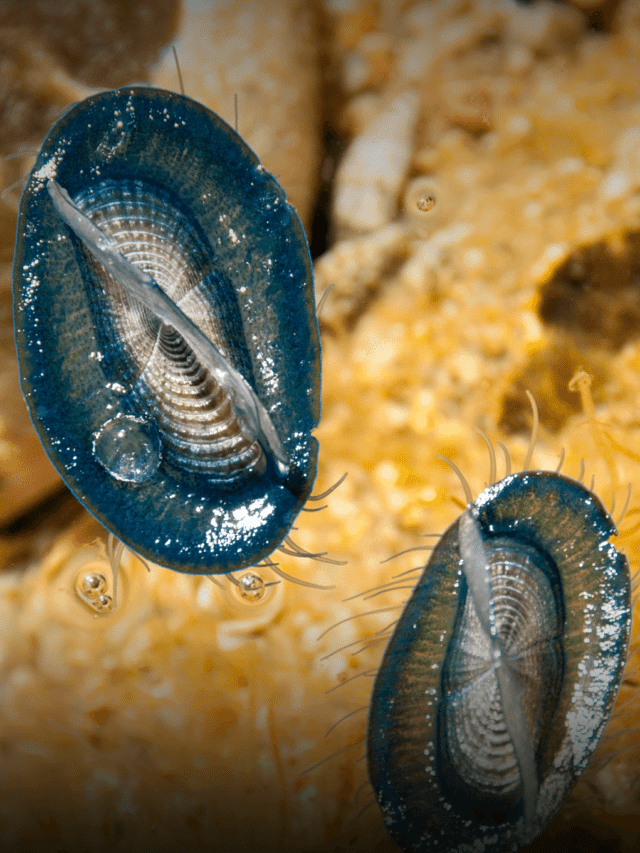

The homogeniser mixes, mashes & agitates the fuel-water molecules to a finely dispersed (spread) & uniformly spread stable water-in-oil emulsion. The fuel & water molecules are broken down nearly 1/20th of their original size. The emulsified fuel droplet at the outlet of the homogeniser looks as below.

As a result of the homogenisation, the broken-down water molecules are trapped inside the fuel molecules, and they co-exist as a stable & uniform emulsion.

When this emulsion is further pumped & eventually reaches the combustion chamber, it comes in contact with the hot compressed air, which causes the water droplets inside the emulsion to evaporate due to heat gain.

As the water turns into steam, it atomizes the fuel, which results in even smaller droplets & better distribution of the fuel in the combustion chamber, thus resulting in complete combustion & a gain in thermal & overall efficiency, besides a reduction in air pollution.

Besides these benefits, it also results in indirect benefits such as reduced maintenance intervals as a result of cleaner, more efficient operations and reduced downtime during planned/routine maintenance due to component parts such as pistons, piston crowns, cylinder liners, exhaust valves, turbochargers, economisers etc. being in a much cleaner condition.

The steam generated due to the evaporation of the water molecules also helps to reduce the exhaust temperatures by producing a cooling effect. This also has an effect of contributing to the overall health of the engine by reducing sooty and sticky carbon deposits on the engine and associated components, as well as reducing/minimising heat-related damage, thereby prolonging their service life.

Conclusion

To conclude, the benefits of Water-in-Fuel Emulsions are manifold, as seen & discussed above. The gain in overall efficiency, reduction in costs and extended life of the engine and components, besides savings in maintenance and reduction in downtime, can be achieved by a relatively small and compact unit, which requires little to no maintenance and can be run with distilled or potable water produced on board the ship.

Therefore, its benefits far outweigh the costs. In addition, due to the compact size, the WFE unit can easily be retrofitted in the engine room of existing vessels.

In the modern shipping industry, where shipowners & operators are constantly grappling over the balance between environmental compliance & the costs of running their vessels, WFE systems, in a similar manner to Exhaust Gas Cleaning Systems, provide an easier, cost-effective and cheaper alternative to the shipowners, who can continue to operate with relative cheaper residual fuels as against costlier distillate fuels and continue to run older ships with a relatively smaller cost of retrofitted technology, as against the enormous cost of procuring new ships.

You might also like to read-

- How Does A Rudder Help In Turning A Ship

- Types of Rudders Used For Ships

- Revolutionary Rudder Force Detection System for Dynamic Positioning Operation

- What Is Lowermost Deck In A Ship?

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used in the article, have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories