Understanding Indicator Diagram and Different Types of Indicator Diagram Deficiencies

Indicator diagrams are used to assess the performance of each unit of the ship’s main engine. It is based on the indicator diagram that the overall performance of the engine is assessed.

Indicator diagrams are taken at regular intervals of time and matched with that of the ship’s sea trial diagrams to check if there is any significant difference in performance. If there is any difference, it is important that the problem is rectified before starting the engine.

Understanding Indication Diagram

There are four types of indicator diagrams:

- Power card

- Draw card

- Compression diagram

- Light spring diagram

With the help of these diagrams, we can determine and interpret the following:

- The compression pressure inside the cylinder

- peak pressure generated inside the cylinder

- The actual power generated

- Faulty combustion chamber parts (worn out piston, liner, rings, etc.) of the particular unit

- Faulty injection parts and wrong fuel timing

- Exhausting and scavenging process

High loading is to be prevented on main engine’s units or else it can lead to several problems such as bearing damage, cracking, etc. It is therefore very important to read these diagrams correctly as they provide several details about the cylinder working pressures and load.

In earlier days, the indicator diagram was taken with the help of mechanical indicator which was to be fitted on top of the indicator cocks.

But nowadays digital pressure indicator instrument is used which is a compact hand held unit. A pressure transducer is mounted on the indicator cocks and connected to the hand held unit know as data acquisition unit with the help of which the indicator diagram can be taken at any moment and displayed on the computer.

An incremental encoder is fitted on the engine and plugged into the data acquisition unit during the time of operation, which provides accurate data about the position of the top dead centre, or of the crankshaft angle.

Preparation and procedure for taking indicator diagram:

- Check the battery of Data Acquisition unit and change/ charge if needed

- Prepare the Digital Pressure indicator instrument and check all the wires/sensors are visually ok

- Do proper PPE, especially high-temperature gloves and eye protection

- Take the reading of all the relevant engine parameters

- Ensure the ship, and its engine is running at a constant speed in open sea

- ensure the weather is calm

- Use correct tool to open the indicator cock valve

- Connect the probe from incremental encoder to data acquisition unit

- Connect the pressure transducer probe to hand held data acquisition unit

- Carefully open the indicator cock of the cylinder for few seconds and blow out the cylinder. It is done to remove any stuck impurity (soot and other combustion particles) inside the cock

- Fix the pressure transducer unit on indicator cock and open the cock to register the cylinder data

- Repeat the procedure for all the cylinders

- After finishing the process, disconnect the pressure transducer probe and keep it aside for cooling it down

- Disconnect the incremental encoder probe from hand held data acquisition unit

- Fill the required data in the Digital Pressure Indicator software and wait for result to be generated

It is possible that the digital pressure indicator instrument is not available in all ships or is not working. A mechanical engine indicator device is provided which consists of springs, drums and pointer to draw the diagram from the engine cylinder’s pressure via indicator cock.

Related Reading:

Why 2-stroke engines are used over 4-stroke engines

How to use main engine performance curve for economical fuel consumption

Procedure for taking indicator diagram using mechanical engine indicator instrument:

- Do proper PPE, especially high-temperature gloves and eye protection

- Take the reading of all the relevant engine parameters

- Ensure the ship, and its engine is running at a constant speed in open sea

- ensure the weather is calm

- Use correct tool to open the indicator cock valve

- Take the paper provided with the instrument and fix it firmly over the drum

- Carefully open the indicator cock of the cylinder for few seconds and blow out the cylinder. It is done to remove any stuck impurity (soot and other combustion particles) inside the cock

- Fix the instrument on the indicator cock so that the cord is firm.

- Draw the atmospheric line with the cock shut

- Slowly open the indicator cock and press the stylus against the paper lightly. Make straight vertical lines as the piston moves up and down and then pull the roller string, till the cycle is drawn on the paper

- Close the indicator cock and remove the instrument

- Ensure the tool does not get exposed to high temperature for an extended period as its mechanical parts like springs, the stylus will respond differently and may affect the accuracy

Similarly, take compression pressure line with the fuel cut off.

How Can You Assess or Interpret Just by Looking at the Card Diagram

The indicator diagram shown above is a normal diagram (Diagrams taken before the use of the engine), and the diagrams that are drawn from the engine are adopted and compared for the deficiency.

Related Reading:

1o Extremely Important Checks For Starting Marine Engines

12 Terminologies Used For Power of Marine Engines

Types of Deficiencies

We will take a look at some of the common defects found in indicator diagrams.

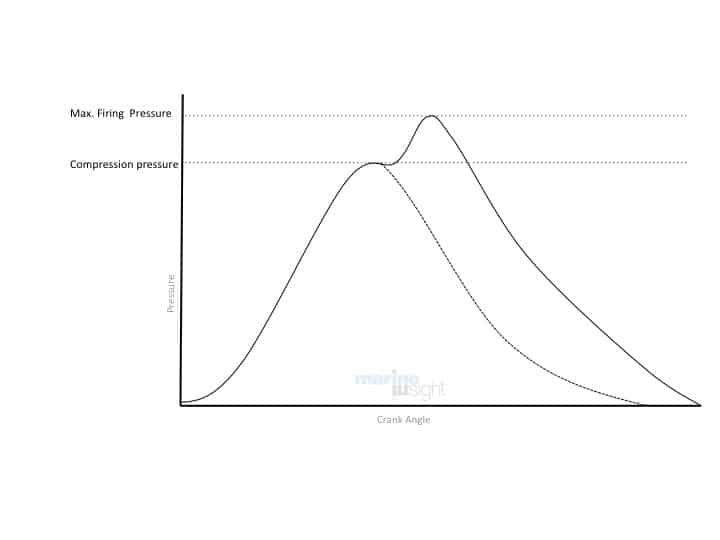

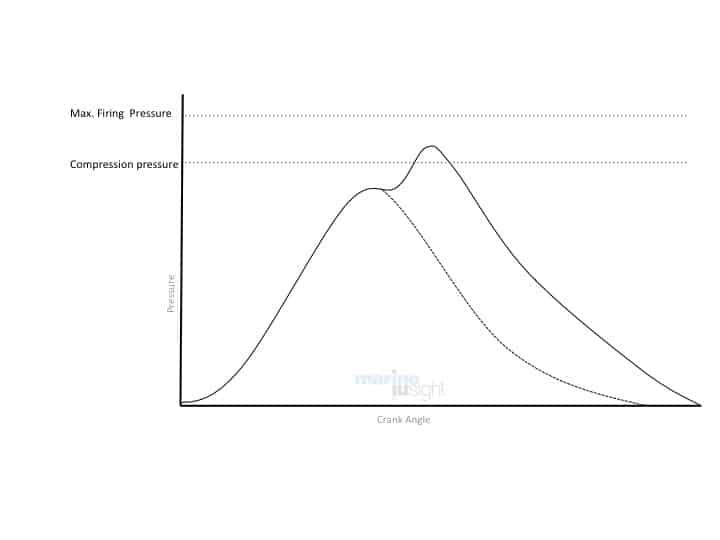

Deficiency type 1

When the above diagram is compared with the general graph, it can be seen that the compression pressure is normal and the maximum firing pressure is too high.

This can be due to early injection, a result of incorrect fuel timing of the cams, wrong VIT setting, or leaking fuel injector.

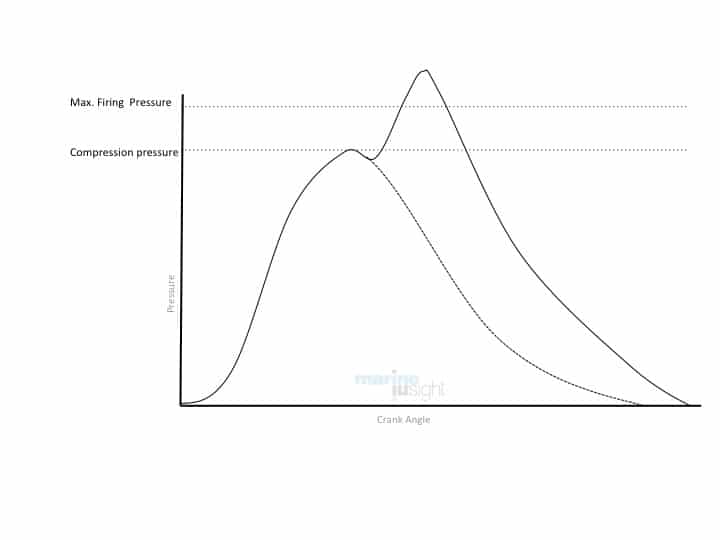

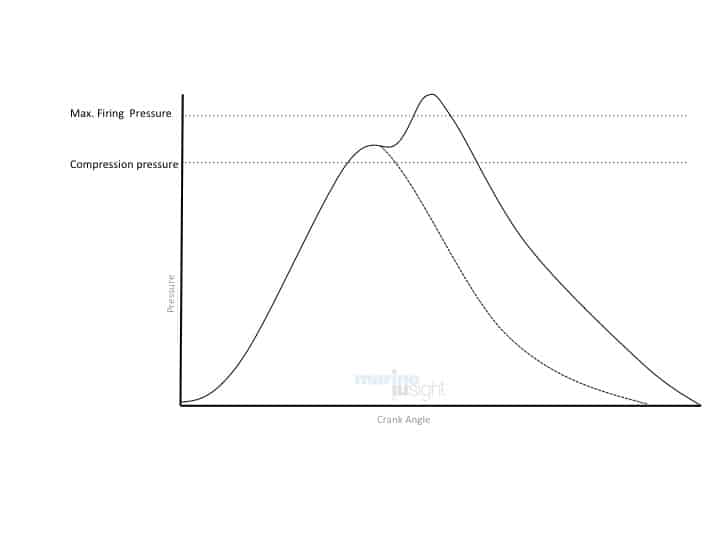

Deficiency Type 2

In this diagram, it can be seen that the compression is same, but the peak pressure is too low.

This effect can be a result of following factors:-

- Bad quality of fuel

- Fuel injector nozzle blocked

- Fuel pumps leaking

- Low fuel pressure

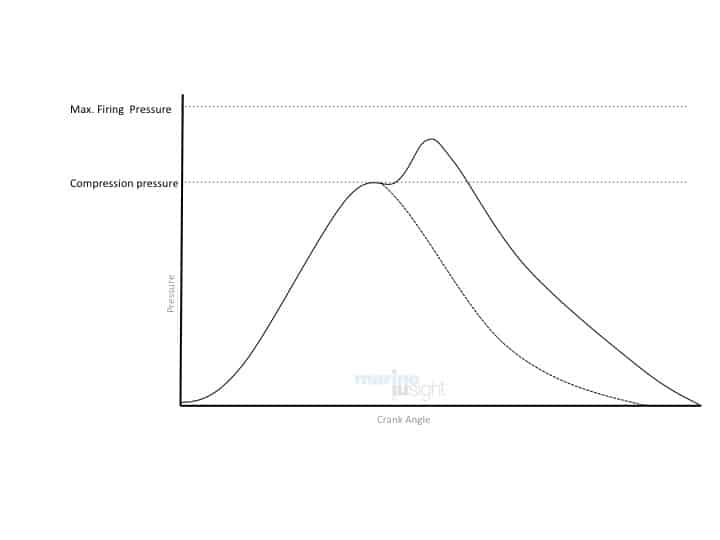

Deficiency Type 3

This diagram shows that the compression pressure is low, and the peak pressure is also too low.

This can be due to the following:

- Leaking exhaust valve

- Leak through piston rings i.e., broken or worn out piston rings

- High Liner wear

- Burnt piston crown

- Low scavenge pressure

Deficiency Type 4

This diagram shows high compression pressure together with high peak pressure.

This can be as a result of the following:

- Exhaust valve opening too late i.e. incorrect exhaust valve timing

- Overload of the engine

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.

for question

thank you for this post sir…. can u pls explain the draw card diagram with fuel injection starting point and ending point in the diagram….

The materials are detailed and educative. Thanks

Slowly open the indicatorcock and press the stylus against the paper lightly. Make straight vertical lines as the piston moves up and down and then pull the roller string, till the cycle is drawn on the paper………….How to pull the roller string, if manually by hand is that correct?

@ALi: Yes.

Why indicator instrument not used for high speed engines

@Hemant: The issue will be getting only a single line on the card due to high speed, and also the inertia in the drum can lead to delays which will not give the correct indicator diagram.

Yes. By hand

What the equipment used to take power cards

Digital instrument is known as DPI and mechanical ones are called mechanical engine indicator instrument