How Single Point Mooring (SPM) Offshore Operation Works?

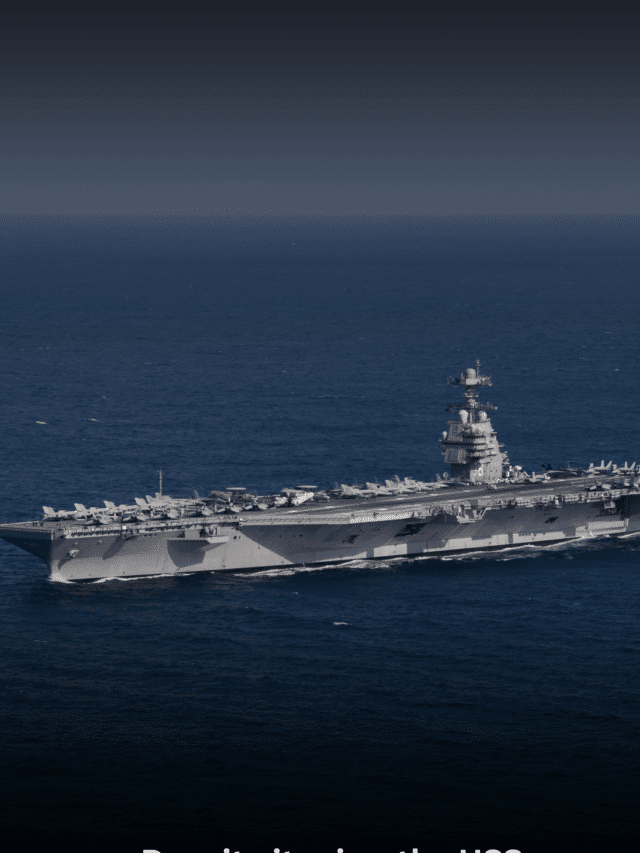

Single point mooring (SPM) is a floating buoy/jetty anchored offshore to allow the handling of liquid cargo such as petroleum products for tanker ships.

SPM is mainly used in areas where a dedicated facility for loading or unloading liquid cargo is not available. Located at a distance of several kilometres from the shore facility and connected using sub-sea and sub-oil pipelines, these single-point mooring (SPM) facilities can even handle vessels of massive capacity such as VLCC.

Single point mooring (SPM) serves as a link between the shore facilities and the tankers for loading or offloading liquid and gas cargo. Some of the major benefits of using SPM are:

- Ability to handle extra large vessels

- Doesn’t require ships to come to the port and thus saves fuel and time

- Ships with high drafts can be moored easily

- Large quality cargo can be easily handled

How Single Point Mooring (SPM) Work?

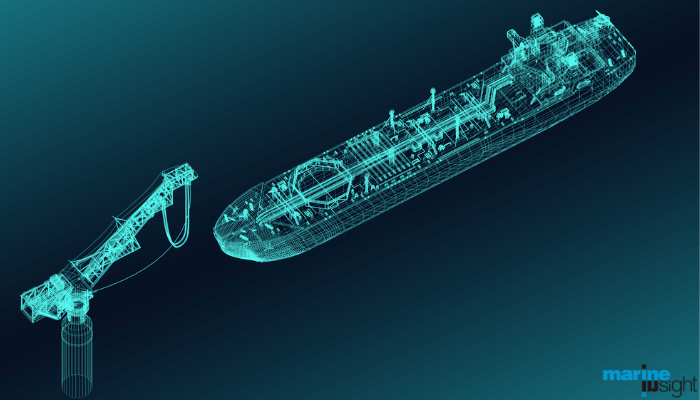

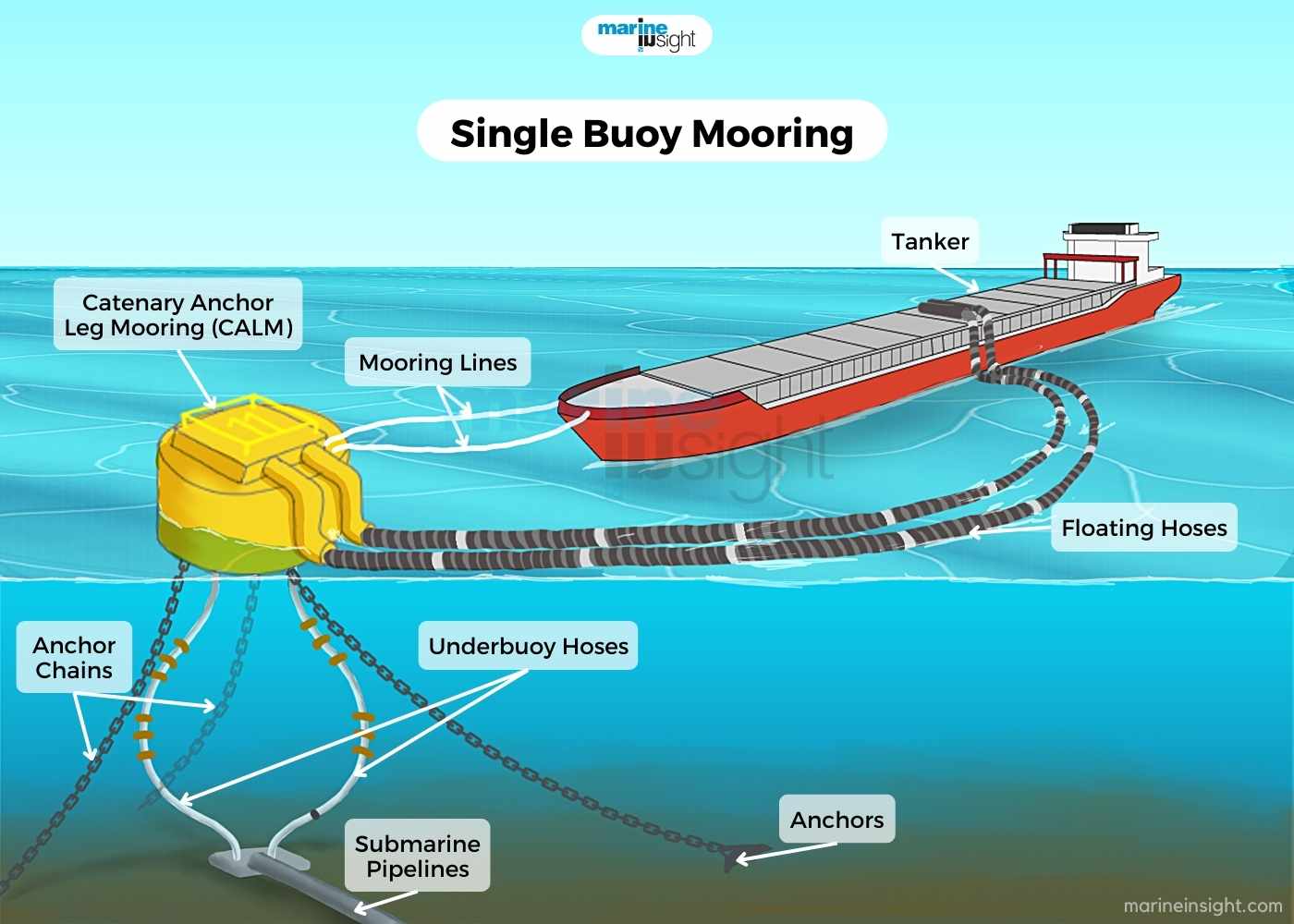

The offshore-anchored loading buoy is divided into different parts having dedicated functionality.

Mooring and anchoring systems, buoy bodies and product transfer systems are the main parts of the SPM.

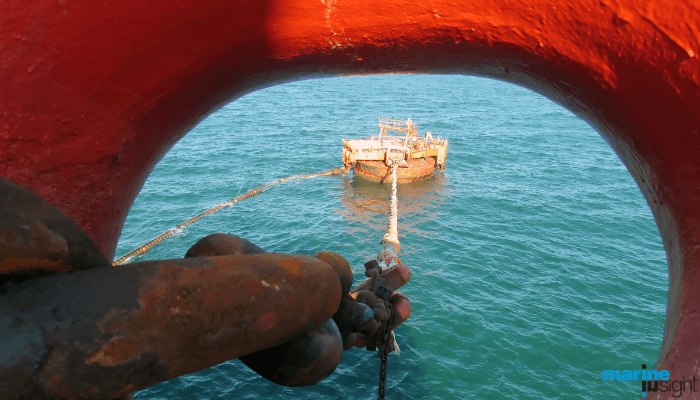

The SPM is moored to the seabed using a mooring arrangement, which includes anchors, anchor chains, chain stoppers etc. The mooring arrangement is such that it permits the buoy to move freely within defined limits, considering wind, waves, current, and tanker ship conditions. The buoy is anchored to the seabed using anchor chains (legs) which are attached to the anchor point (gravity based or piled) on the seabed. Chain stoppers are used to connect the chains to the buoy.

The part of the Single Point Mooring System (buoy body) which is floating above the water has a rotating part which connects to the tanker. The rotating part allows the tanker to get stable at its desired position around the buoy. The tanker is usually moored to the buoy by means of a hawser arrangement, which consists of nylon or polyester ropes shacked to an integrated hook on the buoy deck. Chafe chains are connected at the tanker end of the hawser to prevent damage from tanker fairlead. The mooring systems used for such offshore operations follow the standards put forth by Oil Companies International Marine Forum (OCIMF).

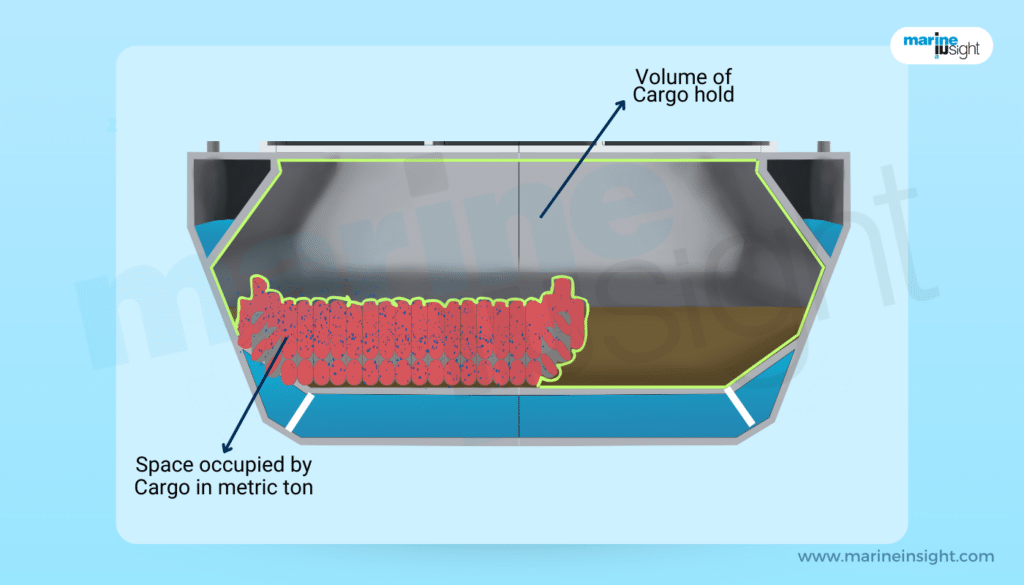

The product transfer system is located at the heart of the mooring buoy. The system transfers products to the tanker from the Pipeline End and Manifold (PLEM) (geostatic location) located on the seabed. Flexible hoses known as risers connect the subsea pipelines to the buoy’s product transfer system. The buoy is connected to the tankers using floating hose strings, which are provided with breakaway couplings ( A particular type of coupling with a breakpoint which will break at a predetermined break load, activating internal valves which will automatically close at both ends and prevent further release of products.) to prevent oil spills.

Single Point Mooring Systems use a swivel system which connects the Pipeline End and Manifold (PLEM) to the buoy. The product swivel system provides the flexibility of movement to the tankers during the transfer of products. This movable pipe-connection system prevents premature hose failure due to traction or bending stresses.

General overview of how single point mooring (SPM) system works

- The tanker ship is moored to the buoy for loading or unloading of cargo.

- A boat landing space on the buoy deck provides access to the buoy for setting up the connections and securing the ship.

- Fenders are used to protect the buoy from unexpected movement of the ship due to bad weather.

- Lifting and handling equipment on the buoy allows for handling of hoses connections and safety tools.

- Once the connections are made, valves are operated from the electrical substation.

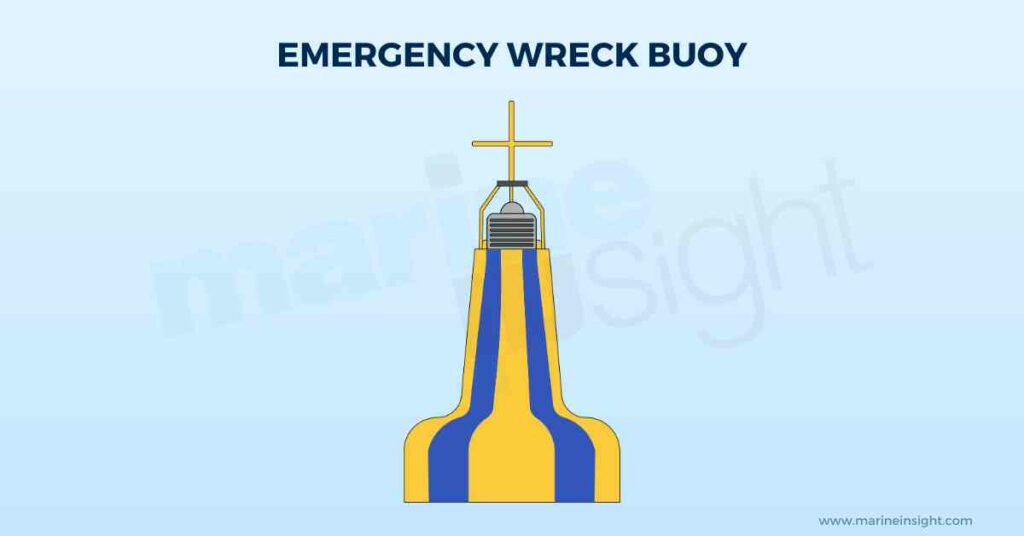

- Necessary alarm systems and navigational aids are provided as safety precautions.

- Liquid cargo is transferred from the geostatic location (Pipeline End and Manifold (PLEM)) to the tanker using the product transfer system of the single-point mooring system.

A General Video on Single Point Mooring Operation

Additional Reference

Single Point Mooring Maintenance and Operations Guide

Single Point Mooring Maintenance and Operations Guide sets out guidelines for operators of SPM terminals and provides a framework and set of procedures that are based on the extensive experience of several companies. It primarily deals with the two most common types of SPM, the CALM (Catenary Anchor Leg Mooring) and the SALM (Single Anchor Leg Mooring).

You may also like to read – How Subsea Components Of ROV Sustain Tremendous Seawater Pressure?

About Author

Raunek Kantharia is a marine engineer turned maritime writer and entrepreneur. After a brief stint at the sea, he founded Marine Insight in 2010. Apart from managing Marine Insight, he also writes for a number of maritime magazines and websites.

Do you have info to share with us ? Suggest a correction

Latest Marine Navigation Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

Raunek, what loading rates are possible in m³/manifold/hour by using SPM ? what is the bottleneck (the vessel itself or the SPM ?)

thank you

Peter

@Peter: Loading rate may vary from 5 to 15m3 depending upon the size, number of the hoses,the head to cover and shore distance.

how do make figuration lezy-s for subsea hose 20 inch depth wather 45 meter . thanks

Respected Raunek,

Many Thanks for your writings; I have learnt a lot to get clear my perceptions about SPM. It will be more grateful of you to send me a detailed presentation on different type of SMPs, their pros & cons along with approximate cost in US Dollars. Have a nice day, and be blessed, always.

MORNING CAN YOU PLS ADVISE IF IT IS NECESSARY TO USE TUGS TO HOLD THE TANKER AT SPM LOADIN/DISCHARGING POINT

Im looking for job at spm.sbm..as mooring master ..

12year experience in this field cerried .

Berthing tnker to sbm..

Plased contac me if any vacancy im looking for.

Rgrds.

we need the drawings and the tech specifications or details of single point mooring can anyone send it

One of the hose of the string has been damaged, we want to change, What is the fast and safest method to replace as we have weather constraint?

we need company intersted for one offer or two calm buoy the tender is ready

you need field

We need calm buoy Maintenance schedule

We provide SPM / SBM Routine IRM (2 weekly, Monthly, 3 Monthly, 6 Monthly, Annual).

SPM Installation, Refurbishing.

SPM Quick respond repair.

Can develop required technical drawing, procedures and dedicated IRM schedule for SPM, PLEM, CLP.

I have design maintenance and operation data about SPM. Please contact me, I am eager for a job

We are in project planning to use spm. However, the pipeline connected between spm fso should be piggable for heavy oil. is it possible to use spm equipped with pigging facilities?thanks Emad Awad

Any designer , manufacturer or supplier of SPM /SBM. Please let me know. What is the approximate cost of installation of SPM/SBM. Please respond.

Is it possible to use Single point mooring (SPM) as a floating buoy/jetty anchored offshore to allow handling of liquid cargo such as Ammonia liquid products for tanker ships. Located at a distance of several kilometers from the shore-facility and connected and using sub-sea sub-ammonia pipelines ended with control valves at pipeline end manifold (PLEM).

Please somebody knows if the followings definitions usually mentioned in the projects, are included in any Rules (API, OCIMF, ABS, BV, DNV or any other ??

– The manoeuvring zone of the SPM is defined by a circle centered on the centre of the SPM with a radius of 1.5 nautical miles minimum.

– The minimum required water depth requested for the tanker in the maneuvering zone (Hmin) is defined as follow:

Hmin = 1.5 Dmax in open sea

Hmin = 1.3 Dmax in sheltered area

I read it in all projects but I don’t know where from are coming ??

Thank you for your comments

I NEED A COMPANY THAT CAN INSTALL AN SPM+PLEM+PIPELINE 3,000m from sea to onshore tank farm

hello

we need to disconnect a tanker from SPM so can some advise or contact us if they are in this field

the pipeline has already been disconnected from

regard

We would you a company to install Vapor recovery unit at rotating SBM

currently my job position is SPM (Single Point Mooring) technician. my job scope involve with SPM and jetty maintenance. I would like anyone can share if there vacancy for me to apply that meet with my experience.tq

Wishing you luck with your Job search 👍