Different Types Of Offshore Oil and Gas Production Structures

In the previous article, we found out how a prospective gas and oil site is searched offshore and what types of mobile drilling platforms are used. Offshore oil and gas exploration requires a constant support from offshore vessels in order to transport temporary drilling units and in fixing fixed units.

After the temporary offshore drilling units have completed their jobs of initial oil / gas production, the site is replaced by permanent offshore oil / gas production structures or platforms. Mentioned below are some of the main types of permanent oil production systems that are used.

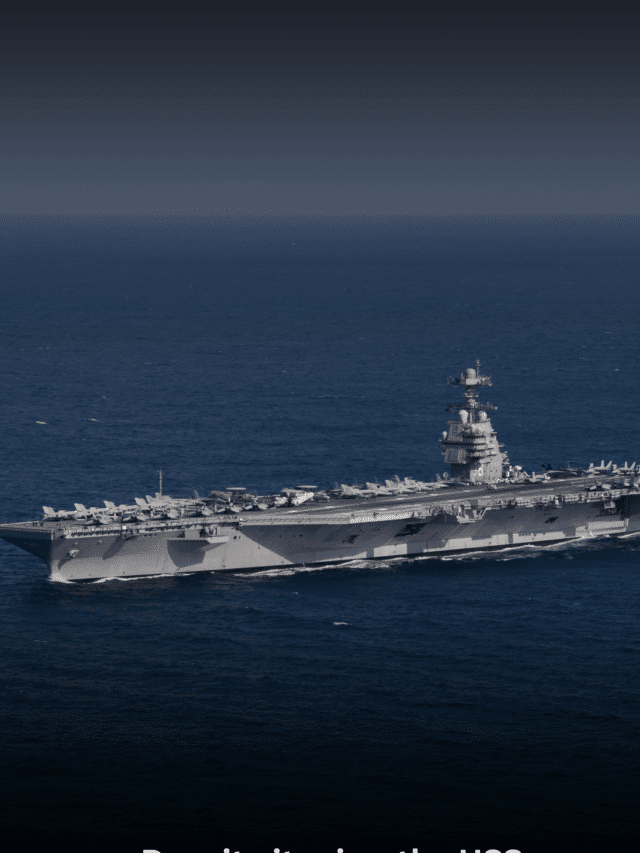

1. Floating Offshore Production Systems: Semi-submersibles and Drill ships are designed to remain afloat hundreds of miles in deep waters. Though floating in nature, they are also a type of permanent oil production systems.

The idea of commissioning these specialized drilling units is to cater for oil and gas production and also be capable of pumping oil / gas to the receiving stations via flexible risers.

Floating, Production, Storage and Offloading (FPSO) is also a type of floating system which is used for production and storage of oil/gas at the sea. Some of the famous FPSOs are Maersk’s FPSOs , Munin Award Winning FPSO, and Shell’s Preclude- The Largest Floating structure in the world.

2. Tension leg platforms (TLP): TLP structures are also a part of the floating production systems which a capable of providing buoyant production facilities. They are moored to the sea bed via the tendons fixed vertically to the structure. The foundation of TLP’s intricate mooring pattern is kept stationary by piling.

They experience more of horizontal stresses due to waves as compared to the vertical movements which are restricted by the tendons fixed to the foundation. These structures are able to drill at depths beyond 5,000 feet and are more stabilized as compared to the other ultra deep water drilling units.

3. Spar Platforms: For drilling wells beyond 10,000 feet, naval architects have designed a type of drilling and production platform which has a hollow cylindrical hull that can descend upto a sea depth of 200 meters. This are called Spar Platforms. It is secured to the ocean floor by a complex network of cables and tendons.

The weight of the cylindrical hull stabilises the drilling platform and caters for the drilling risers to descend upto the drilling well on the sea floor.

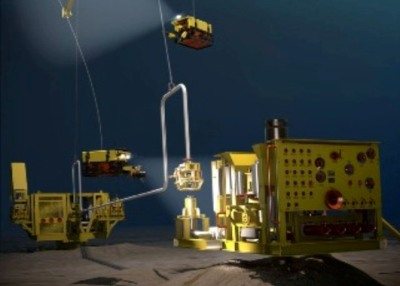

4. Subsea Production System: As the name suggests, this system is based on the idea where wellheads are mounted on the sea floor after the wells have been drilled by one of the many deep sea drilling platforms.

The wellheads are remotely controlled and their automated system is so designed that it allows for transporting the oil or gas directly to the production facilities using a network of undersea pipelines and risers.

Apart from those mentioned above, shuttle tankers are also used in offshore oil production systems.

As technology advancements are progressively made, deep water exploration possess superior challenges for all the operating parties. These massive structures are home to some highly improved and advanced systems, machineries and equipments for carrying out the coveted job of offshore drilling.

Image Credits: loc-group, offshore-technology, myspacecdn, subseaworldnews

Do you have info to share with us ? Suggest a correction

About Author

Bikram Pal Singh is a professional mariner and blogger. He has sailed extensively, serving on various Oil tankers and Offshore Vessels. He enjoys reading and compiling notes about critical shipboard operations and crew psychology.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories