7 Important Points For Safe Lightering Operations On Ships

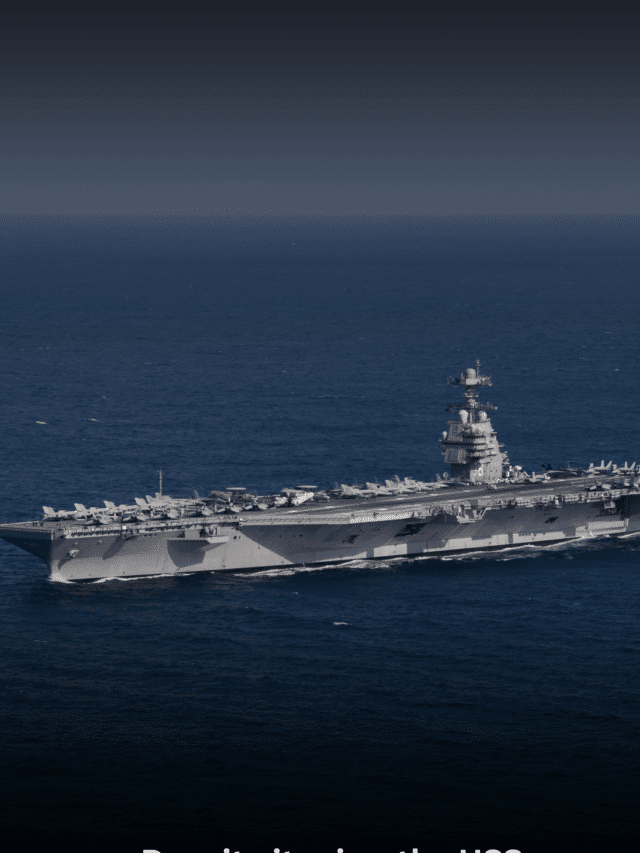

The STS (Ship-to-Ship) transfer of oil, as well as dry bulk cargoes, is a fairly common practice these days given the size of the ships have increased four folds in the past few decades.

Theories and experience have time and again proven that observance and adherence to proper procedures, along with fair weather and sea, can result in a potentially dangerous operation concluded safely.

Lightering, also at times called ‘Lighterage,’ is considered to be an operation that primarily deals with the transfer of wet and dry cargoes between ships of differing sizes, or how we better know it as a cargo transfer operation at sea between the Mother Vessel and the Daughter Vessel a.k.a Lighter Barges or even Lighter Ships.

The process is usually undertaken within the facilities of the port, so as to reduce the draught of the vessel for entering the inland waterways of the port or to that effect sit alongside the wharf.

Some ports have the process as a part of their routine operations and even have set procedures laid down in their regulations, guidelines & manuals.

STS operation / Lightering between ships is carried out worldwide, viz., US Gulf, Eastern and Western US ports, North Sea areas, West African region, Persian Gulf, S. E. Asian ports are some examples.

Although the STS operation and lightering have most procedures in common, which have also been discussed earlier, there are a few relevant elements that we feel should not be overseen while engaging in such critical operations.

1. Person In Charge

Generally, the STS or a Lightering operation is carried out by an operations expert or a STS superintendent or sometimes either of the Ships’ Captains concerned.

The idea is to appoint a PIC or person in-charge to be a sole commandant, fundamentally overlooking and deciding the critical factors for assessing the risks involved and safely completing the cargo transfer operations.

Generally, the STS expert is an ex-mariner who will look into supervision, coordination and authorization of all the events involved, including mooring / unmooring of the vessels.

Worldwide, most companies employ specialized agencies that provide such services.

2. Master’s Knowledge and Responsibility

The Masters of the vessels have to be somewhat familiar with the risks involved during wet or dry cargo transfer operations.

Sometimes, saving the ship from a disaster by jettisoning the cargo to another vessel (if conditions permit) is also underlined as a lightering operation and at these times, Masters are the only personnel to decide and judge how safe and sure the procedures will be.

So, being unfamiliar with such an operation would be considered acceptable in some instances, but, being without knowledge is impermissible.

The Master is responsible for the safety of the crew, cargo and the environment and should accept his responsibilities as an overall in charge of his team without prejudice.

Masters of the ships involved in the lightering operation must ensure that their vessels have compatible cargo handling equipment, mooring equipment and likewise.

Each aspect of such operation is considered to be critical. So, if the STS / Lightering operations in charge rule out or overlook even minute obstacles faced during ship to ship approaches or even mooring / unmooring the vessels, a mishap could be unavoidable.

Hence, considering the risks involved, adherence to the proper procedures is vital.

Company, Port and STS Guidelines coupled with usage of specific operational checklists prove to be a great way to ensure risks involved are not overlooked or any safety information left unnoticed.

3. Communication

Good and clear communication between the vessels is crucial for efficient cargo transfer operations. Agreeing upon a common mode of communication such as via working marine VHF / UHF frequencies and understanding and communicating via a common language is essential.

Communications should be kept brief, clear, concise and be well established for the operations. From confirming the operations’ rendezvous point to engaging in mooring and unmooring activities, all related communications should be under the PIC’s supervision; better if written contact is established and ascertained via verbal confirmation.

Communications should include:

– Initial Contact prior approaching for operations

– Mutually agreed contacting/communicating channels

– Emergency contact points (Port, Company and National Spill Response)

– Emergency and ‘Abort’ instructions

– Relevant international Sound and Day / Night Signals

– Safety messages transmitted via VHF during the operation

– Weather messages

4. Mooring / Unmooring

Mooring the vessels at sea requires a certain amount of competence, and so the STS experts are called in to support the Ship Masters and overlook the mooring operation.

Mooring vessels at sea is even more complicated than mooring them alongside berth. Although it doesn’t require special equipment, it does require an efficient hand to safely conclude the berthing / unberthing process. The things to be kept in mind to complete such critical operations are as follows-

Appropriately sized tyre fenders, namely the Yokohama ones, should be deployed either by the mother vessel or the lighter vessel. This will ensure two things, one, avoiding structural damages during ship to ship contact and on the other hand the rubberised tyre fenders will prevent any accumulation of static between the two vessels during the STS transfer process. Fenders also provide to keeping a safe distance between the two vessels once they are tied up.

Mooring lines used for berthing should be of good construction, material and be resilient enough to absorb all the forces generated during the operation. This will also ensure safe cargo transfer operation.

5. Cargo and Use of Cargo Transfer Equipment

It is imperative to understand what cargo must be transferred from one vessel to another. Compatible cargo equipment must be kept readily available for the operation. Cranes and Derricks should be in working order with their max loads tested and certified, wet cargo transfer hoses should be of relevant size with matching connector couplings and should be of sufficient length and have been tested to max liquid pressure limits.

Dangers of transferring harmful cargoes must be made aware to all involved in the operation. Handling such cargoes require special equipment and protective gear.

For example, personnel working for large oil tankers Lightering off the US Gulf coast that are usually involved with cargo transfers and which may contain high levels of harmful Hydrogen Sulphide choose to work in a vapour free environment or the crew members of large bulkers carrying out a coal discharge at sea and the crew of the smaller lighter vessels must use equipment that detect harmful levels of methane in the cargo.

The use of inert gas as a fire fighting medium and other similar methods of overcoming emergency situations must be well outlined and understood by the personnel.

6. Weather

Decent weather conditions play an important role for all critical marine-based operations to be safely accomplished, and ‘Lightering’ is considered no different.

Sometimes when the cargo transfer is carried out off port / sheltered limits, and heavy weather makes a fall, the operations have to be aborted indefinitely, amounting to loss in time and money.

So a constant vigilant check should be maintained by all involved parties for the weather forecasts and all communication recorded appropriately.

Dry Cargo ships may have to stop the cargo operation from batten down their hatches during rain adding to additional delays.

Weather clauses are hence included in the contract note to protect all parties from paying up either demurrage or despatch.

7. Operational Checklists

Maritime organisations such as ICS or OCIMF and others from around the world have helped improve industrial safety and have aided in disseminating quality education through a variety of guidelines and recommendations.

Following their STS and Lightering guidelines and relevant operational ‘Checklists’ are clearly the best way to get through critical operations, safely.

Companies, too, have them in their management system, and so do the port authorities.

It should be kept in mind that both the vessels involved in the Lightering operation may have different operating procedures and a varied set of personnel handling the process.

Hence, it is strongly implied that all such personnel involved in the cargo transfer operation must be alert and non-complacent to the generic safety procedures on board.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Latest Shipboard Guidelines Articles You Would Like:

Do you have info to share with us ? Suggest a correction

About Author

Bikram Pal Singh is a professional mariner and blogger. He has sailed extensively, serving on various Oil tankers and Offshore Vessels. He enjoys reading and compiling notes about critical shipboard operations and crew psychology.

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

Very professionnal!

I am 1st class driver. Work in barge 2000tons. Goa port.

I want to engine maintenance book in Cummins engine.

And overall barge maintenance book.

Please send.

Very interesting article.

You mention weather conditions are critical for these kind of operations, which is totally clear.

Do you have knowledge of STS transfers of LNG on tsunami exposed sites? Would tsunami be an “no-go” condition for a STS LNG.

Thanks

@Nicolas: You need to consult the concerned port/ harbour guidelines. They have the report of wind and sea conditions criteria normally used by operating companies in the area. These standards are based on historical observations and experience in handling the vessels under prevalent conditions.

Well written article.